Kayan aiki

Muna amfani da kayan da aka shigo da su da kuma sanannen gida mai suna "Three High" tungsten carbide na farko daga manyan masana'antun a matsayin albarkatun ƙasa.

Premium Materials

Abubuwan Al'ada

Muna ɗaukar tsarin samar da siminti na ciminti na ƙasa da ƙasa don kera samfuran gami masu inganci.

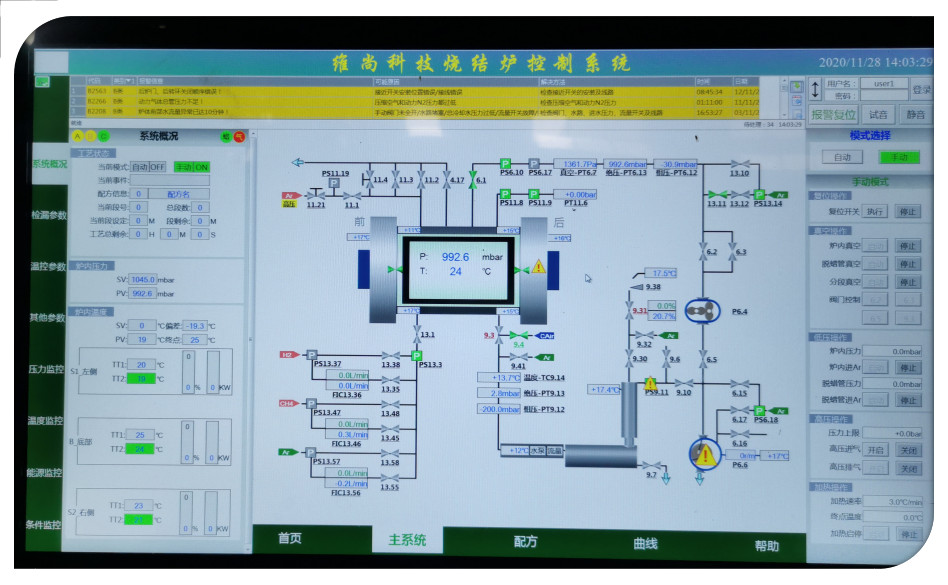

An haɓaka taron shirye-shiryen shirye-shiryen milling ɗin da aka haɗe don samun nasara mai hankali da sarrafawa ta atomatik.Ta hanyar tsarin sarrafawa mai sarrafa kansa, muna sarrafa sigogi kamar saurin juyawa, lokaci, zafin jiki, da sauransu. Ana faɗakar da duk wani abu mara kyau da sauri, kuma ana gudanar da cikakken bincike na bayanai don ci gaba da haɓaka sigogin sarrafa tsari.

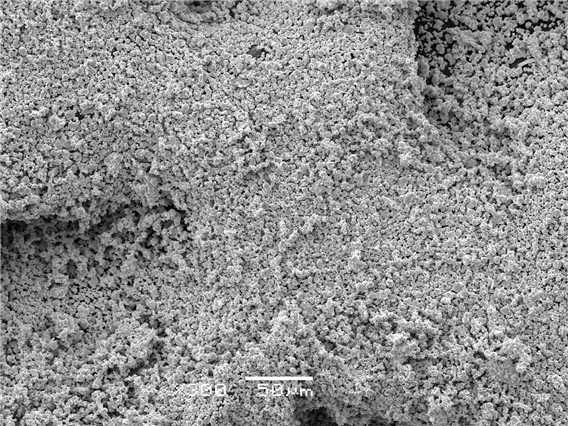

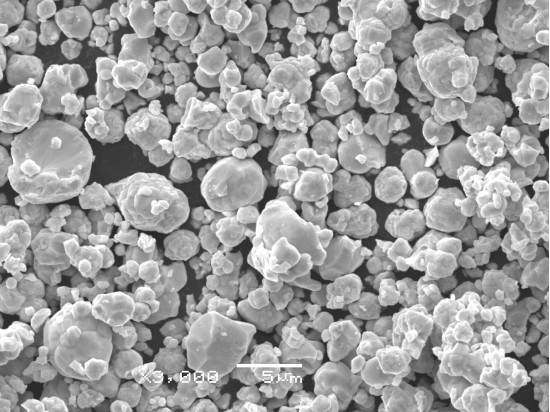

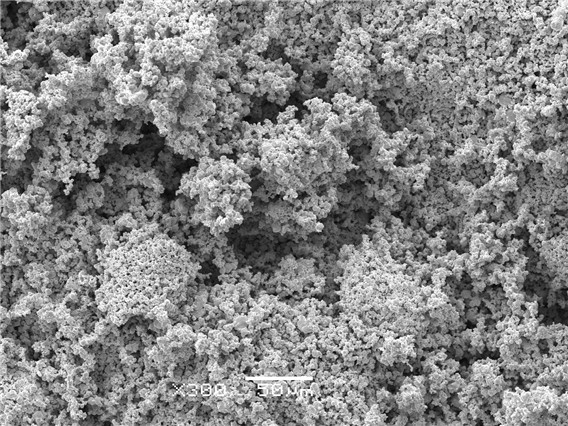

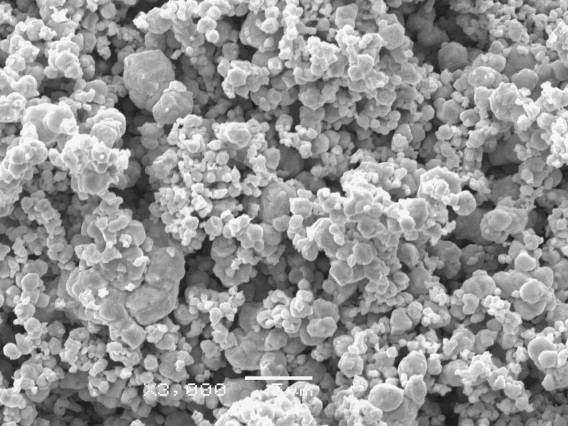

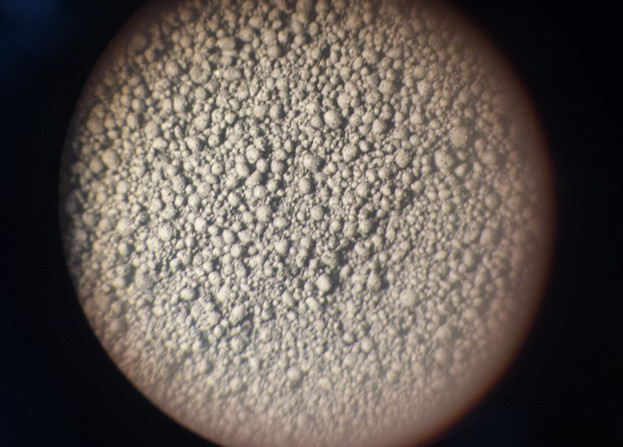

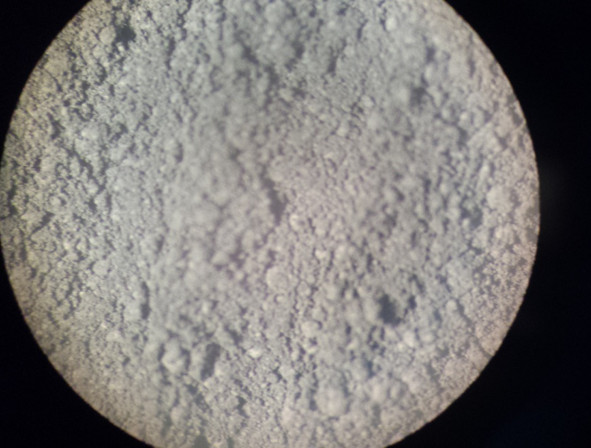

Mun yi amfani da internatio-nally ci-gaba SPRAY bushewa granulation tech-nology, wanda kwatanta-ed zuwa gargajiya manual granulation, yadda ya kamata ware iska da ƙura, sakamakon uniformly sized foda barbashi da kuma m inganci.

Tattalin Arziki da Gyara:

A cikin tsarin aikin mu, muna amfani da injuna na ci gaba da suka haɗa da 60-ton TPA atomatik latsa da 100-ton atomatik na'ura mai aiki da karfin ruwa.Wannan yana haifar da rarrabuwar kawuna iri-iri na ɗanyen samfur mai yawa da babban daidaito a cikin girman samfur.Taron bitar yana kiyaye ingantacciyar iska mai matsi, zafin jiki na tsawon shekara da kula da zafi, da kuma matakan tsabtace iska don tabbatar da yanayin samarwa mara gurɓata da ingancin samfur a cikin tsarin masana'antu.

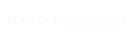

A cikin shekaru 50 da suka gabata, fasahar simintin siminti na siminti ta sami ci gaba na ci gaba daga tanderun hydrogen zuwa tanderun da ba a so, kuma a ƙarshe zuwa matsa lamba ta tanderu.Sintering-taimaka matsi ya fito a matsayin dabara na gaba-gaba a duk duniya.Wannan tsarin yana haɗa rarrabuwa, vacuum sintering, da kuma matsa lamba sintering cikin mataki guda, rage porosity samfurin da kuma cimma wani matakin na gami yawa akin zuwa cikakken m kayan.

Tsarin Kula da Ingancin Matakai Tara a cikin Samar da Alloy:

1. Gwajin Sinadari da Abubuwan Jiki na Raw Material

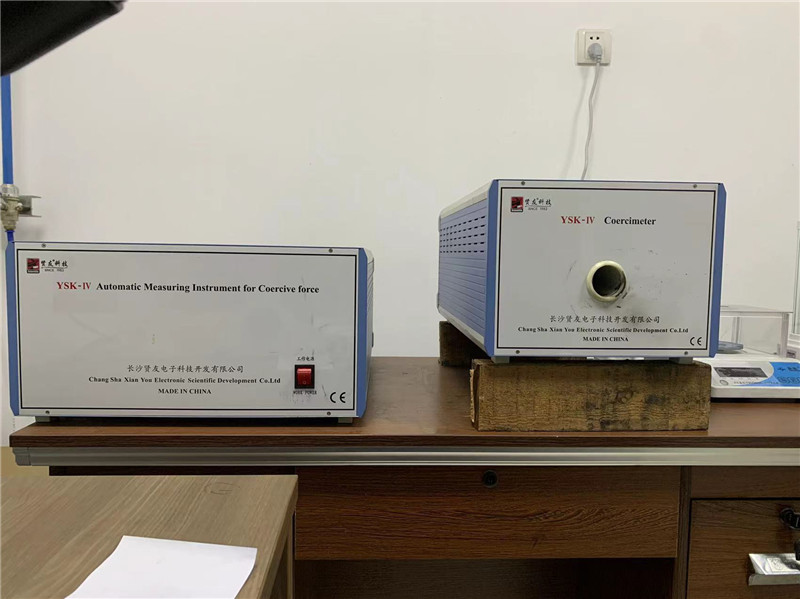

2. Gwajin Ƙwallon Ƙwallon Ƙwallon Ƙwallon Ƙwallon Ƙwallon Ƙwallon Ƙwallon Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwaƙwalwa na Ƙwaƙwalwa na Ƙaƙa )

3. Samfurori da Gwajin Halayen Jiki na Abubuwan Haɗaɗɗen Kwallo

4. Ganewa ta hanyar Samfuri da Gwaji na Abubuwan Jiki na Gaɗaɗɗen Fasa-Milled Materials

5. Gwajin Aikin Farko na Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwaƙwalwa na Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙaƙwalwa na Ƙaƙwalwa na Ƙaƙwalwar Ƙaƙwalwar Ƙaƙwalwa na Ƙaƙwalwa )

6. Binciken Kai na Ƙarfafa Ƙwararrun Ƙwararrun Ƙwararrun Ƙwararru

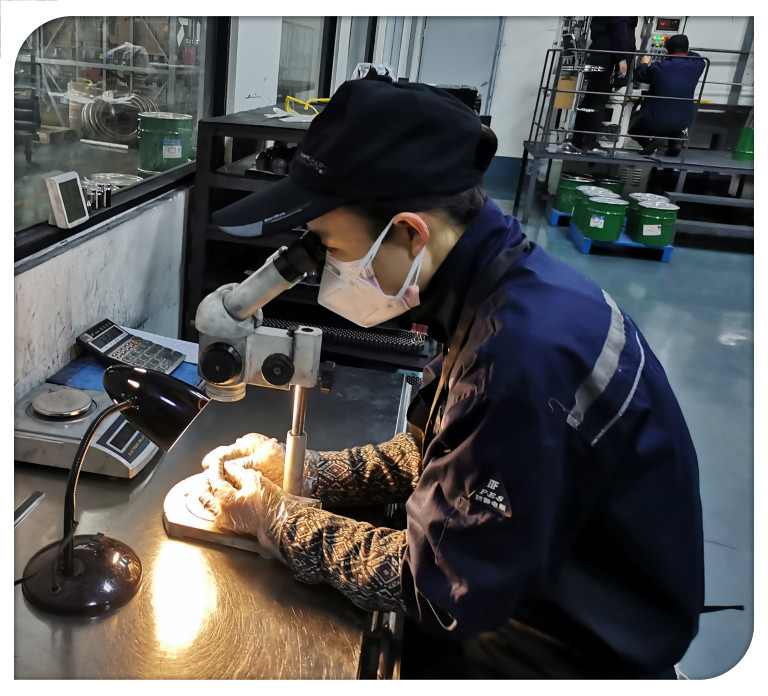

7. Sake duba Inganci ta Ma'aikatan Ingantattun Ma'aikata

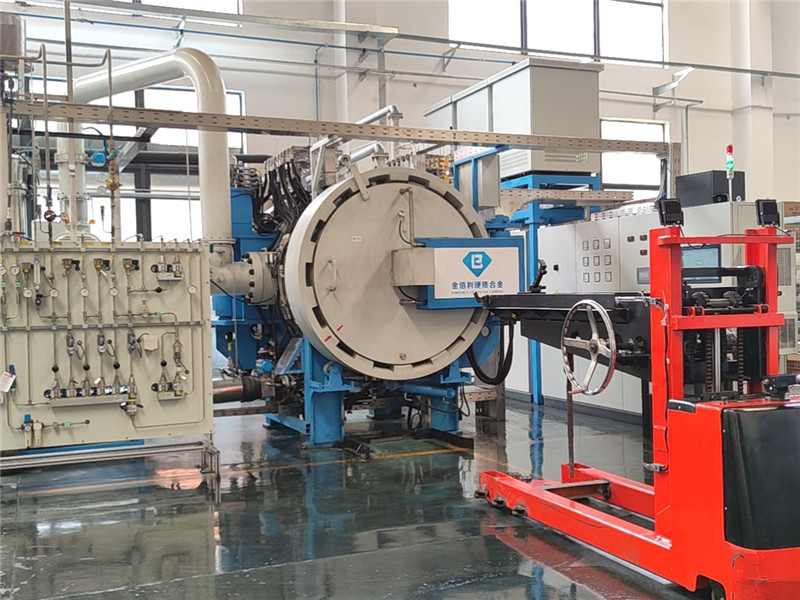

8. Gwajin Halayen Jiki da Injiniya na Kayayyakin Ƙirar Ƙarshe

9. Duban Ƙarshen Samfuran Samfura, Girma, Bayyanar, da Lalacewa.